Varnish/Resin

Voltatex® 4200 Impregnating Resin by Axalta

Sort By

Refine Your Search

Showing all 3 results

-

Part # VOLTATEX4200TOTE

Part # VOLTATEX4200TOTEVoltatex® 4200 Impregnating Resin 1000KG

$18,430.00×- Material

- Polyester Imide polymer with methacrylate monomer

- Color

- Yellow-brownish

- Shelf Life

- 8 Months

- Flash Point

- Product does not sustain combustion

- Container Size

- 1000KG (233.8 GL)

- Temperature - C

- 220˚ C Class R

- Gel Time

- 7 - 13 Minutes

- Viscosity

- 2000 Centipoise

- VOC

- all VOC‘s <0.2 lbs/gallon

- Cure Time

- 1-2 Hours @ 150˚ C (depends on motor size)

-

Part # VOLTATEX4200

Part # VOLTATEX4200Voltatex® 4200 Impregnating Resin 200KG

$3,864.00×- Material

- Polyester Imide polymer with methacrylate monomer

- Color

- Yellow-brownish

- Shelf Life

- 8 Months

- Flash Point

- Product does not sustain combustion

- Container Size

- 200KG (46.8 GL)

- Temperature - C

- 220˚ C Class R

- Gel Time

- 7 - 13 Minutes

- Viscosity

- 2000 Centipoise

- VOC

- all VOC‘s <0.2 lbs/gallon

- Cure Time

- 1-2 Hours @ 150˚ C (depends on motor size)

-

Part # VOLTATEX420020KG

Part # VOLTATEX420020KGVoltatex® 4200 Impregnating Resin 20KG

$425.20×- Material

- Polyester Imide polymer with methacrylate monomer

- Color

- Yellow-brownish

- Shelf Life

- 8 Months

- Flash Point

- Product does not sustain combustion

- Container Size

- 20KG (4.7Gl)

- Temperature - C

- 220˚ C Class R

- Gel Time

- 7 - 13 Minutes

- Viscosity

- 2000 Centipoise

- VOC

- all VOC‘s <0.2 lbs/gallon

- Cure Time

- 1-2 Hours @ 150˚ C (depends on motor size)

Need something Custom? We can make it in the foundry.

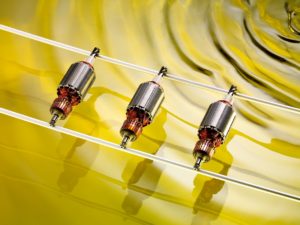

Ask JenkinsVoltatex® 4200 Impregnating Resin by Axalta can be used in dip and bake, VPI, and trickle applications. All Axalta Voltatex® 4200 Impregnating Resins are UL-approved, making the UL-approval for our customers much easier.

What is Voltatex® 4200 Impregnating Resin by Axalta used for?

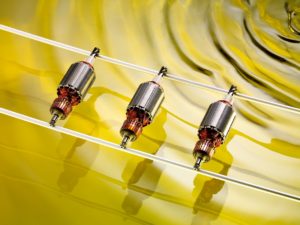

Voltatex® Impregnating Resins are used in insulation systems for electric motors, large machines, fast revolving rotors and hermetic motors, and transformers.

Are Voltatex® 4200 Impregnating Resin by Axalta UL-approved?

All Voltatex® Impregnating Resins are UL-approved, making the UL-approval for our customers much easier. The change in technology towards the electrical-UV and hot-dipping process, in combination with the low emission or monomer free Voltatex® resins, leads to effective solutions and outstanding quality performance.

What is the recommended cure time when using Voltatex® 4200 Impregnating Resin by Axalta?

Voltatex® 4200 Impregnating Resin by Axalta needs about 1-2 hours to cure at 150˚ C. This timing depends on motor size. If you have questions email [email protected].

What type of hardener, accelerator or thinner is needed to work with Voltatex® 4200 Impregnating Resin by Axalta?

Voltatex® 4200 is supplied ready to use and does not require the addition of a hardener, accelerator or thinner.

How is Voltatex® 4200 Impregnating Resin by Axalta applied?

The impregnating resin can be applied by using: 1) trickle and roll/dip-processes 2) all kinds of common dip & bake equipment, including vacuum and VPI 3) hot dipping processes 4) resistance heating processes with oven post-curing 5) resistance heating and gelling processes (“Hot-Dip-Gel-Process”).