Just Add Water. Weld Smart. Weld Clean.

The H20Weld Water Welder is the smart, sustainable solution for modern brazing. Just add distilled water—no gas cylinders, no storage, no emissions. It produces a clean flame that emits only water vapor, keeping your workspace safe and breathable. With a focused flame to reduce overheating, and an ergonomic torch for all-day comfort, it’s built for precision and ease. Plus, it cuts costs and boosts productivity—twice the speed, zero gas bills, and total peace of mind.

H20Weld Water Welders

Efficiency, Quality and Precision

Since 1981, H20Weld Water Welders have been designed and manufactured with the end user in mind. These oxyhydrogen gas generators use electrolysis of distilled water to produce a clean, efficient flame for brazing, welding, and soldering. With decades of experience and a strong focus on research and development, H20Weld gas generators have a global reputation for innovation, safety, and sustainability. Like all Jenkins-approved products,, we rely on this welder daily—both in the shop and on-site—for its precision flame and dependable performance. Its environmentally safe design makes it ideal for even the most sensitive field and customer environments.

Key Product Features

- Efficiency & Cost Savings: Generates gas on demand from distilled water, reducing operating costs by up to 80–90% compared to traditional systems. No gas purchases or transportation required.

- Precision & Quality: Automatic gas mixing ensures a perfect stoichiometric ratio. The neutral, focused flame minimizes overheating and improves brazing accuracy.

- Safety & Health: No gas cylinders, no hydrogen storage, and no risk of explosion. The flame produces only water vapor—no CO₂ or toxic emissions—creating a safer, cleaner work environment.

- Eco-Friendly: 100% green technology. The only by-product is water vapor, making it ideal for environmentally conscious operations.

- Ergonomic & Practical: Lightweight torches and modular support systems enhance operator comfort and workflow efficiency.

Applications

The oxyhydrogen flame is ideal for working with copper, brass, aluminum, nickel, bronze, stainless steel, and even precious metals like gold. H20Weld Water Welding systems are ideal for a wide range of industries and uses, including:

- Electric motor and transformer manufacturing and repair

- HVAC and refrigeration systems

- Solar panel collectors

- Hard metal saw blade production

- Artistic and industrial metalwork (e.g., statues, trophies, chandeliers)

- Glasswork and jewelry manufacturing

Why Choose H2OWeld Water Welders?

Safety & Health First

H2O Weld Water Welders eliminate the need for conventional gas cylinders, removing the risk of explosion and making your workspace significantly safer. Operating at low pressure (under 0.5 BAR / <10 PSI) and producing gas only on demand, the system ensures there’s no hydrogen storage and no toxic fumes. The result? A cleaner, healthier environment for operators—with a flame that emits only water vapor and zero CO₂.

Precision You Can Trust

Our system automatically mixes hydrogen and oxygen to achieve the perfect stoichiometric ratio—no manual adjustments, no guesswork. The focused flame minimizes overheating, delivering consistent, high-quality brazing every time.

Designed for Comfort

With a lightweight, ergonomic torch, H2O Weld is built for ease of use and operator comfort. Whether you’re working on delicate components or extended jobs, the design helps reduce fatigue and improve control.

Efficiency That Pays Off

H2O Weld Water Welders are not only safer—they’re smarter. By generating gas from distilled water, you eliminate gas costs, transportation, and storage. Plus, with up to 2× faster brazing, you’ll boost productivity while cutting operational expenses.

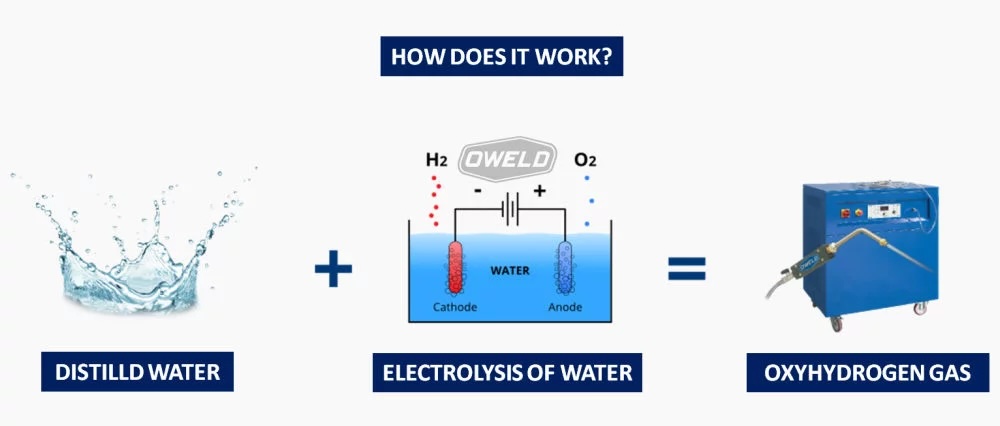

How it Works

ELECTROLYSIS OF WATER

A water molecule (H20) is composed of two hydrogen atoms and one oxygen atom. The molecule is colorless, odorless,and tasteless. The hydrogen atoms in water are joined to the central oxygen atom by single polar covalent bonds. Electrolysis is an electrochemical process by which electrical energy is used to promote chemical reactions that occur at electrodes. In more simple terms, electrolysis is the decomposition of a compound by passing an electric current through it.

H2O Weld Water Welder – Clean, Safe, and Efficient Oxyhydrogen Brazing

The H2O Weld Water Welder is a cutting-edge oxyhydrogen gas generator designed for precision brazing, welding, and soldering—powered entirely by distilled water. Using advanced electrolysis technology, it produces hydrogen and oxygen on demand, eliminating the need for gas cylinders, storage, and transportation. With a flame that emits only water vapor, it ensures a safer, healthier, and eco-friendly work environment with zero CO₂ emissions and no toxic fumes.

Engineered for performance and practicality, the system features automatic gas mixing for a perfectly balanced flame, low-pressure operation (<0.5 BAR), and an ergonomic torch for operator comfort. Ideal for industries such as HVAC, electric motor repair, transformer manufacturing, and metalwork, the H2O Weld delivers up to 90% cost savings and 2× faster brazing—making it the smart, sustainable choice for modern workshops and field operations.