Critical Asset Maintenance Solutions

Our Critical Asset Maintenance Solutions are backed by an experienced engineering team and span set-up, equipment storage, monitoring, analysis, repair, return and training. We understand that your uptime is critical to your business, which is why we offer the level of service you need – provided by a repair partner you can trust.

Predictive Maintenance Services

When it comes to extending the life of your equipment, routine maintenance is just the beginning. Our engineers and technicians incorporate monitoring and maintenance best practices into a custom, integrated predictive maintenance program that’s backed by equipment data trends.SETUP

- Critical equipment & baseline identification

- Data collection frequency

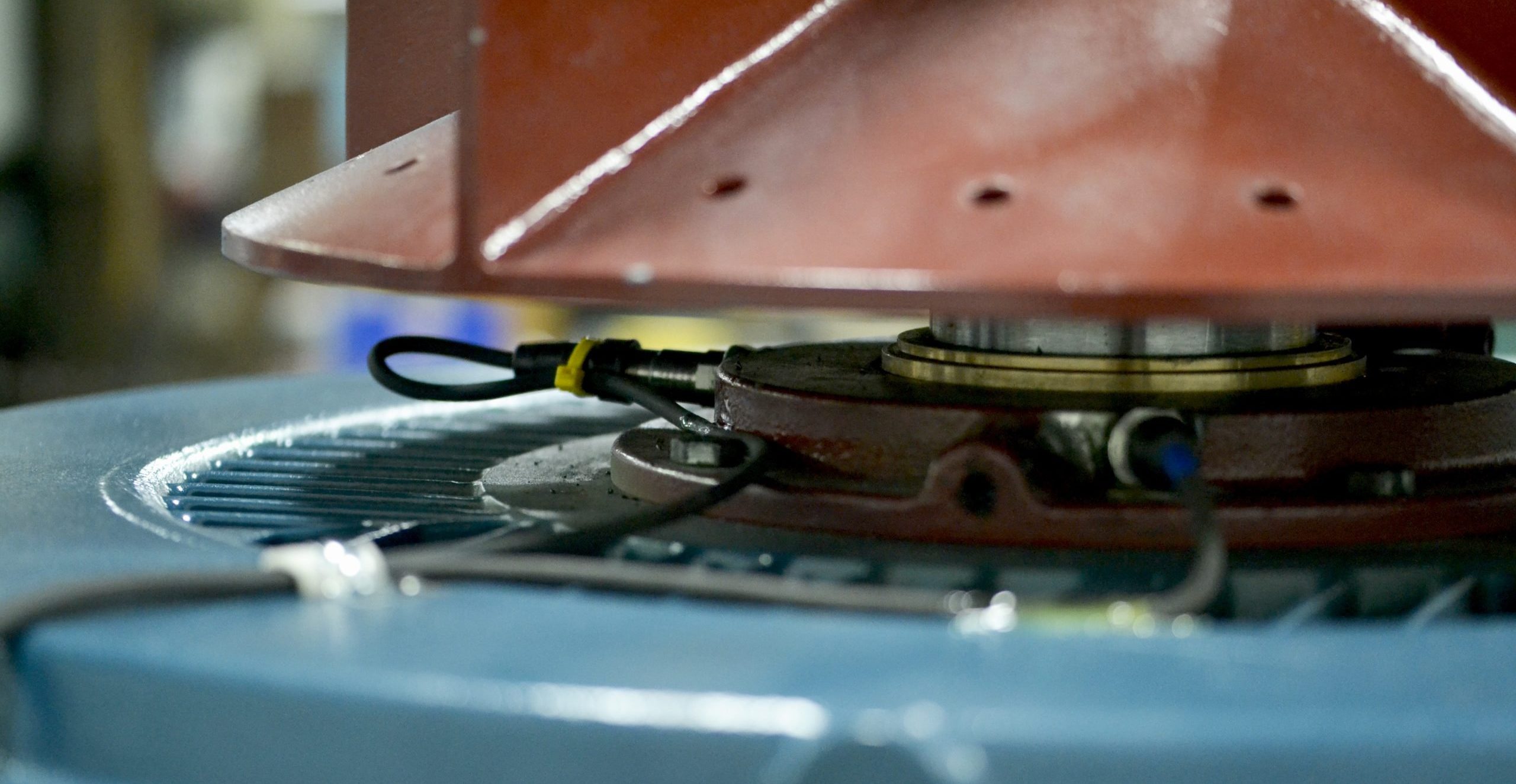

- Sensor installation for critical and hard to access equipment

- Climate controlled storage for critical spares

ONGOING MONITORING & MAINTENANCE

- On-site data collection routes

- Remote monitoring of equipment data

- Data analysis and trend reporting

- Monthly maintenance and testing of stored equipment

OUTAGE PLANNING & REPAIR

- Scheduling of planned outages and repairs

- Equipment repair, re-installation and alignment

- Testing and installation of spares

DATA COLLECTION TYPES

- Vibration Analysis

- Thermal Imaging

- Motor Circuit Analysis

- Power Quality

- Ultrasound (Lubrication)